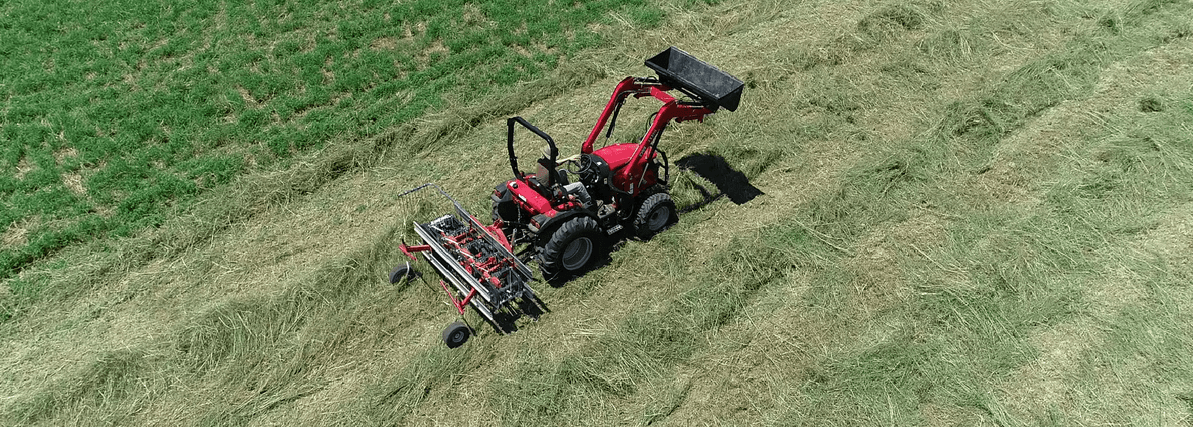

The Raking Process

Over the past few months we have been covering the basics of hay production. We have already discussed mowing and tedding. In this blog we will discuss the raking process.

Once your fields have cured, it’s time to rake. Though by this point in the process your sights are set on a field full of sweet-smelling bales, raking should never be overlooked in its importance to the final product. Raking done well can increase the quality of a bale while raking done poorly will surely decrease it.

The purpose of raking is to turn the hay one last time and to form the windrow necessary for baling. The first step in raking is to properly set your rake. This simple and important task will keep your bales from being contaminated with dirt and other debris. Tines should skim just above the ground. This prevents the bending and wearing down of tines and reduces the amount of time and money spent on rake maintenance. Be sure to check any operator manuals for the best ways to set your specific style of rake.

Finding the optimum dryness for your hay before raking is also of great importance. Raking hay into windrows too soon will prevent the underside from getting the exposure to air and sun that it needs. Furthermore, raking hay that is too damp when you plan to immediately bale it will result in moldy hay.

Raking should be done when the hay is nearly dry. While you can invest in a moisture meter to help you determine the dryness of your hay, there is a simple technique you can use to do the same. While walking through the field give several samples the quick “twist test”. To do this, simply grab a fistful of hay and twist it with a circular motion. If the stems break easily, the hay is cured. If it bends, it is not.

Though it seems counter-intuitive, raking hay when it is too dry can have equally negative consequences. This is especially true for leafy legumes like clover and alfalfa. Raked when overly dry, these forages lose precious leaf material—material that contains two thirds of the protein and 75 percent of the digestible nutrients in alfalfa hay. Therefore, it is recommended that producers avoid raking clover and alfalfa when moisture levels are less than 35 to 40 percent.

The time of day that you rake is important too. Generally, raking should be done during the late morning once the dew has dried and the sun is near its peak. If possible, it’s best to then allow at least two hours before baling. This timing prevents the dew’s moisture from being tossed to the dark underside of the windrow and still gives the newly turned underside enough sun exposure to dry before baling. One exception to this timing would be when hay is overly dry. In this case, brittle hay is less likely to shatter when raked while the dew is still on.

The type of rake you use will affect the timing of raking. Some hay rakes, like rotary rakes and belt rakes, create a tall, fluffy windrow. With this type of rake, you have the option of raking before the hay is fully dried. Oftentimes this means the day before you would like to bale. With good drying conditions, hay will finish drying in these airy windrows. If you are using a wheel rake or side-delivery rake (often called a rollabar rake), you will need to wait until the hay is completely dry before raking it into windrows. This is because these rakes will tend to twist the hay tightly, preventing good airflow and thus slow further drying. In either case, a key to successful baling is creating consistently sized windrows, and raking in a pattern that will be easy to follow with the baler. Stick to straight lines and gentle curves for best results.

Raking pattern depends a lot on the thickness of the hay and the size of windrow you wish to create. You want a windrow that is as large as your baler can comfortably “eat” without leaving any hay behind. Contrary to what you may think, it is not necessary to follow the same path with the rake that you did when you cut the hay. Usually the rake is a different width than the hay cutter, so trying to follow the same path is inefficient. Most of the time your windrows will be further apart than your mower’s cutting width.

When hay is very thick, you may not have much choice but to simply rake the first row on the outside of the field toward the middle in order to have clearance around the field edge. You can then turn around and rake the remainder outward in a spiraling pattern toward the middle. This means that except for the first windrow on the outer edge, they will all be no larger than can be made with a single rake width.

When you have lighter cuttings, especially later in the season, you may find that it makes more sense to double, triple, or even quadruple rake your windrows. Double raking typically is achieved by going across the field and back on adjacent paths, depositing the second pass on top of the first. Pick a line across the full width of the field, and work off of that line, finishing up edges and corners at the end.

Raking is somewhat of an art. Expertise will come with time, and the best way to learn is to get on the tractor and do it. Eventually you will get the feel of the process, and once you do, the segue between cutting and baling your hay will become second nature.

Recent Posts

-

The Subcompact Economy Hay Package: Your Gateway to Small-Farm Hay Production

For small-acreage farmers who want to step into hay production with confidence, affordability, a …Feb 6th 2026 -

Power Harrows for Spring Soil Prep: The Must-Have Tool for Small Farms

Spring is coming fast — and for growers, livestock managers, and land stewards, that means it’s …Feb 1st 2026 -

The Evolution of the Kubota BX Series: How a Sub-Compact Became a Powerhouse

While we here at Tractor Tools Direct do not sell Kubota BX tractors themselves, we do sell plen …Jan 15th 2026